Telecommunications: Cell Sites

With concerns of global warming and the geopolitical issues surrounding foreign oil, there is a renewed emphasis on producing energy from clean, renewable sources that help lower the carbon impact of power generation and provide for future energy stability. Wind power is now a mature technology, and it is emerging as one of the most environmentally-friendly and energy-efficient systems to date.

However, wind generated power has its own particular set of environmental issues to deal with. Wind farms are usually located in harsh environments with extreme temperatures (for example, offshore temperatures may fall below -10°C), or excessive dust, and vibration.

Communication between wind turbine towers is another major issue since wind farms typically span vast distances that may go on for miles. And due to the sheer height of wind turbines, they are also prone to lightning, GPR and electrical events that result in catastrophic turbine damage and outage which result in costly repairs, downtime, and lost revenues. Networking and communications products used in these applications require industrial-grade durability in order to withstand such conditions.

Given these circumstances, it is essential for wind farms to use only rugged and highly reliable communications and networking equipment that employ the use of fiber optics. Fiber optics have superior dielectric properties and are immune to GPR events and temperature extremes that could interfere with communication, monitoring and control of the wind farm and its control facility.

Fiber Optics From the Start

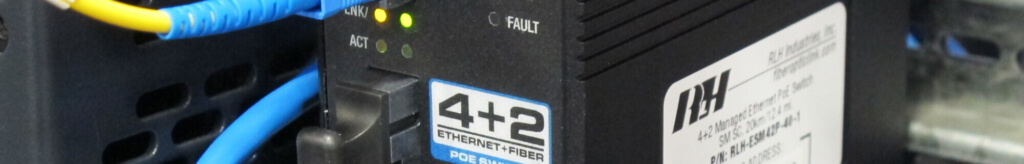

Since 2002 RLH Industries, Inc. has been manufacturing and providing fiber optic equipment to accommodate the wind energy industry. Our engineering philosophy has been to concentrate on providing the best technology for the application because of superior performance and protection, not simply because it seems like another way to expand our product line.

Our experience in fiber optic communications goes back to 1988, and copper-based isolation equipment has never been part of our product line. Fiber optics are simply the best way to protect networks from lightning strikes, GPR events and power surges, and we have been dedicated to bringing our fiber optic link products in line with the needs of the emerging wind energy industry.

Hardened at Our Core

Wind energy Industrial network components must be capable of withstanding harsh environmental conditions such as extreme temperature ranges, and RLH industrial hardened analog and digital copper to fiber voice/data equipment provides isolation from environmental and outside disturbances in environments ranging from –40°C – +70°C. Add to this our vigorous standards compliance, and you have a perfect fit for the particular requirements of the wind energy industry.

Industry Standards

- IEEE 1590-2003

- IEEE 487-2000 (Annex F)

- FCC-Part-15

- Motorola Standard 59